Key Takeaways

- The Swedish giant IKEA tops the list as the world’s largest furniture producer by revenue and volume.

- Ashley Furniture Industries ranks second, driven by U.S. market strength.

- China’s massive manufacturing base gives companies like Sunlum and Kuka a sheer production advantage.

- Revenue, units produced, and geographic reach are the three main metrics used to rank producers.

- Understanding the leaders helps suppliers, investors, and designers spot trends and partnership opportunities.

When you ask, “Who is the largest producer of furniture in the world?” the answer isn’t a single mystery brand but a clear market leader backed by hard numbers. In 2023 IKEA generated roughly largest furniture producer revenue of $44.6billion and shipped over 300million items across 50 countries. That scale dwarfs any other individual company and makes IKEA the benchmark for the entire industry.

Below we’ll break down why IKEA holds the crown, compare it with the next three global players, and show how you can use those insights whether you’re sourcing components, investing in a supply chain, or simply curious about where your next sofa might come from.

What Makes a Company the “Largest” Furniture Producer?

There are three core attributes we use to decide the ranking:

- Revenue - total sales from furniture and related home‑goods.

- Production volume - number of individual units (chairs, tables, beds) manufactured or assembled in a year.

- Geographic footprint - how many markets the company serves and the breadth of its distribution network.

Many rankings focus on revenue because it’s the most reliable public data point. Production volume can be harder to verify, especially for firms that outsource to third‑party factories, but industry reports from Euromonitor and Statista provide credible estimates.

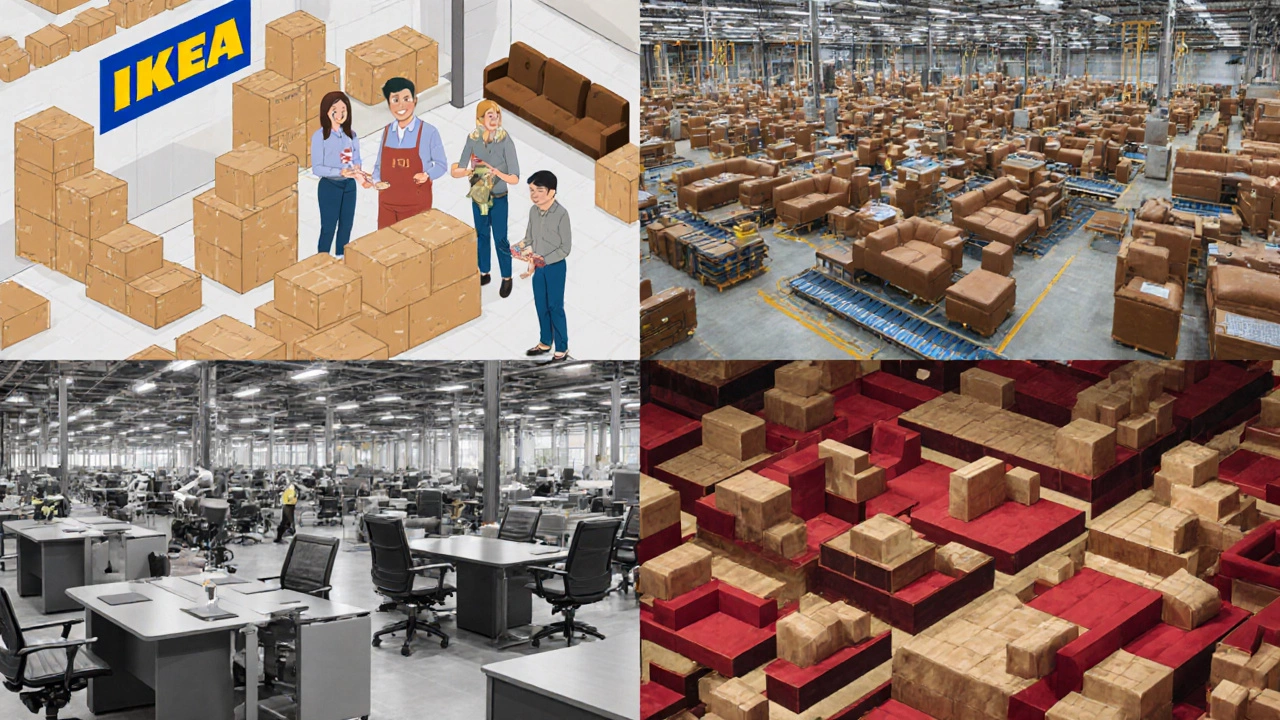

Top Global Furniture Producers in 2023

The table below captures the four companies that dominate the sector based on the three metrics above.

| Company | Headquarters | 2023 Revenue (USDbn) | Units Produced (millions) | Key Markets |

|---|---|---|---|---|

| IKEA - Swedish multinational retailer and manufacturer | Sweden | 44.6 | 300+ | Europe, North America, Asia‑Pacific |

| Ashley Furniture Industries - U.S. furniture maker and retailer | USA | 12.4 | 150 | United States, Canada, Mexico |

| Sunlum - Chinese furniture manufacturer specializing in office and contract furniture | China | 9.8 | 200 | China, Southeast Asia, Europe |

| Kuka Home - Chinese home‑furniture maker focused on upholstered goods | China | 7.2 | 180 | China, Middle East, South America |

Why IKEA Leads the Pack

Several strategic moves keep IKEA ahead of rivals:

- Vertical integration: While IKEA outsources many components, it owns a global network of 60+ distribution centers and 200+ stores that act as both sales points and final‑assembly hubs.

- Design‑for‑assembly: Flat‑pack designs shrink shipping volume by up to 70%, slashing logistics costs and allowing massive order volumes.

- Supply‑chain transparency: IKEA’s IWAY code of conduct forces suppliers to meet strict environmental and labor standards, which builds brand trust and reduces disruption risk.

- Market diversification: Presence in high‑growth markets such as India and Vietnam offsets slower demand in mature Europe.

Financially, IKEA’s 2023 profit margin of 6.5% outperformed most peers, thanks to economies of scale and a pricing strategy that targets the mass‑market segment.

Who Challenges IKEA and How They Differ

While IKEA dominates, the other three companies bring unique strengths:

Ashley Furniture Industries focuses on high‑margin, fully assembled** pieces for the American market. Its vertically integrated factories in Mississippi and North Carolina give it tighter control over quality, but limited international reach caps overall revenue.

Sunlum excels in contract office furniture. By supplying large corporate campuses, Sunlum can move huge order volumes in a single shipment, which inflates its production figures despite a lower brand profile.

Kuka Home dominates the upholstered segment in China, leveraging low‑cost labor and advanced CNC cutting for fabrics. Its growth is fuelled by rapid urbanization in Tier‑2 Chinese cities.

Understanding these nuances helps you decide whether to partner with a mass‑market behemoth or a niche specialist.

How to Use This Insight

If you’re a supplier, aim for IKEA’s flat‑pack specifications; they require precision‑cut wood, standardized hardware, and recyclable packaging. For smaller manufacturers, targeting Ashley’s “ready‑to‑use” market can yield higher per‑unit margins.

Investors often look at the revenue and margin trends of the top four. IKEA’s consistent double‑digit revenue growth (average 7% YoY since 2018) signals a stable cash flow, while Sunlum’s rapid expansion in the Asia‑Pacific office sector suggests a high‑growth opportunity.

Designers can also benefit: IKEA’s open‑source design guidelines are publicly available, allowing independent creators to develop compatible accessories that can be sold through the IKEA marketplace.

Future Outlook: What Could Shift the Rankings?

Three forces could reshape the hierarchy over the next five years:

- Automation: Companies that adopt AI‑driven CNC machining and robotic assembly lines could boost production volume without adding labor costs. Sunlum is already piloting such robots in its Guangdong factory.

- Sustainability regulations: Europe’s upcoming “Circular Furniture Act” will require 50% of sold furniture to be reusable or recyclable by 2030. IKEA’s long‑standing circular‑economy programs give it a head‑start, but other firms will need to invest heavily to comply.

- Emerging market consumerisation: As middle‑class incomes rise in Africa and Latin America, demand for affordable, flat‑pack furniture will surge. Companies that can set up low‑cost regional assembly hubs (e.g., Kuka Home) could leapfrog IKEA in those markets.

Keeping an eye on these trends will help you anticipate where the next “largest producer” might emerge.

Frequently Asked Questions

Is IKEA actually a manufacturer or just a retailer?

IKEA designs its own products and owns a global network of factories and distribution centers. While many components are sourced from third‑party suppliers, IKEA controls the final assembly and packaging, making it a hybrid manufacturer‑retailer.

How does IKEA’s flat‑pack model affect production numbers?

Flat‑pack design reduces shipping volume by up to 70%, allowing IKEA to ship more units per container. This efficiency inflates its reported production volume compared to companies that ship assembled furniture.

Which company is the second‑largest furniture producer worldwide?

Ashley Furniture Industries holds the second spot, with 2023 revenue of $12.4billion and roughly 150million units produced, mainly serving North America.

What role does China play in global furniture manufacturing?

China supplies the raw materials and hosts massive factories for both domestic brands like Sunlum and international OEMs. Its low labor costs and extensive supply chain give Chinese firms a production‑volume advantage, though brand recognition abroad varies.

How can a small supplier get onto IKEA’s supply chain?

Suppliers must meet IKEA’s IWAY standards, submit detailed cost‑sheet proposals, and demonstrate the ability to produce to flat‑pack specifications. Pilot projects often start with a single product line before scaling up.

Write a comment