Ever looked at a bag of chips or a carton of milk and thought about the crazy journey it made from a farm onto your table? That journey is packed with steps called 'unit operations.' These are the basic moves every food goes through when it gets processed—think washing, mixing, chopping, heating, or freezing. Without these steps, food would be unsafe, inconsistent, and honestly, a lot less tasty.

If you're working in food processing or just curious why some frozen veggies taste fresher than others, understanding unit operations opens your eyes to the choices factories make every day. Tiny tweaks—like how quick vegetables get blanched or how long cookie dough gets mixed—change flavor, safety, and even shelf life. And if you ever want to work in the industry, knowing these steps is non-negotiable. You’ll spot weak points fast and fix problems before a batch goes sideways.

- What Are Unit Operations in Food Processing?

- Key Types of Unit Operations

- Real-World Examples and Tips

- Why Unit Operations Matter

What Are Unit Operations in Food Processing?

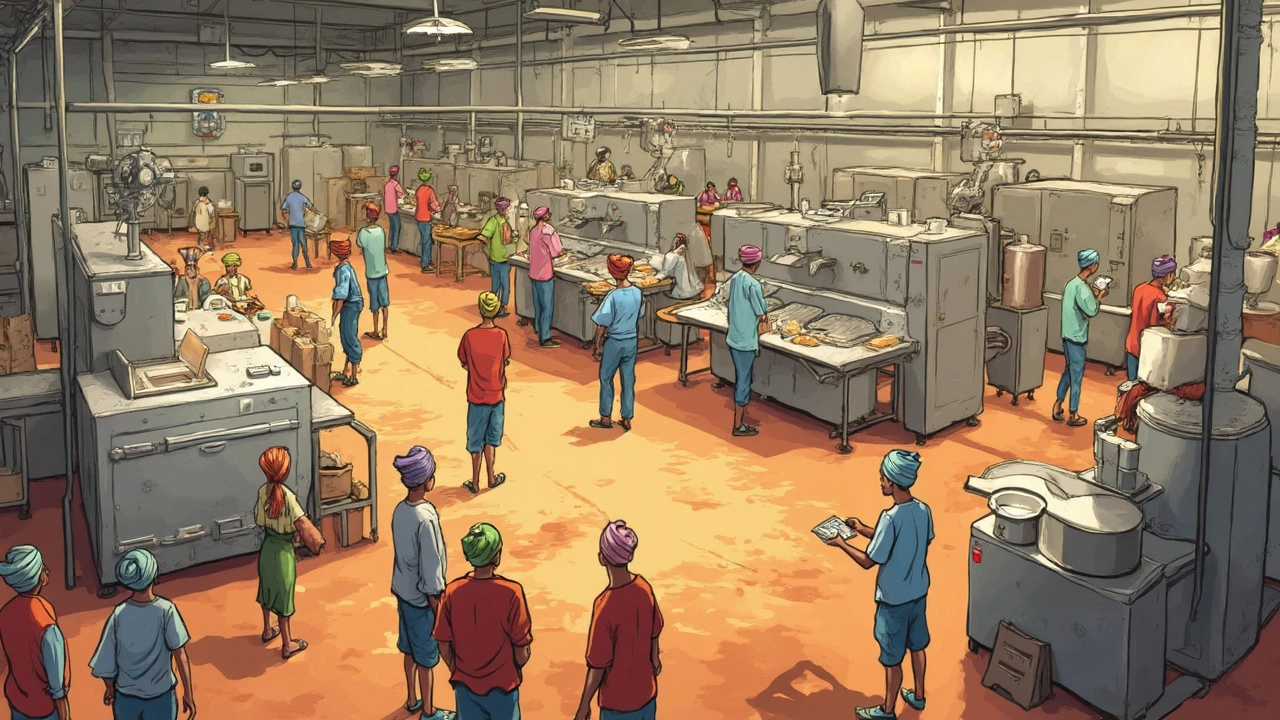

If you peel back all the fancy equipment and high-tech sensors, every food factory counts on the same basic steps, called unit operations. These are the building blocks that turn raw crops, meat, or milk into the food you actually want to eat. The term “unit operation” first popped up in the early 1900s when engineers realized almost every processed food, no matter how different, goes through a common set of physical changes. It doesn’t matter if you’re making bread, ketchup, or cheese—every product gets shaped by these steps.

To put it simply, a unit operation is a single action that makes physical changes to food without changing its basic chemical nature. Stuff like grinding coffee, boiling vegetables, filtering juice, or chilling soda. Some foods go through just a few of these steps. Others, like baby formula or instant noodles, can have a dozen or more.

The main reasons for having these steps are pretty practical. You want to keep the food safe, boost shelf life, make it look and taste better, and make sure every batch comes out the same. Each unit operation targets a specific problem, like removing dirt, killing bacteria, or locking in flavor. The table below shows how common each main unit operation is in different food categories:

| Unit Operation | Used in Dairy | Used in Snacks | Used in Canned Foods |

|---|---|---|---|

| Cleaning | Yes | Yes | Yes |

| Mixing/Blending | Yes | Yes | Sometimes |

| Heat Treatment | Yes | Rare | Yes |

| Filtration/Separation | Yes | No | Sometimes |

| Drying/Dehydration | No | Yes | No |

Even basic stuff like cleaning and chopping are massive when done on an industrial scale. For example, a modern potato chip plant can wash and slice more than 30,000 pounds of potatoes in one hour. If any of these steps slips up, you end up with recalls, complaints, or worse. So, these unit operations aren’t just techy terms—they’re what holds the factory together day after day.

Key Types of Unit Operations

Every food factory leans on a few main unit operations. Each has a clear job, whether it’s getting rid of dirt, changing texture, or locking in flavor. These steps are the muscle behind any smooth-running food plant and knowing them helps you spot where products can turn great or go bad fast.

- Mechanical Operations: Chopping, slicing, grinding, mixing—these steps break raw ingredients down or mix them up. Mixing is huge in baking and snack production, making sure every bite tastes the same. Chopping or grinding is key for sauces and spreads, where texture matters a ton.

- Thermal Operations: Heating and cooling rank at the top in terms of impact. Boiling, pasteurization, and blanching all use heat to kill germs or soften food. Freezing and chilling slow spoilage by dropping the temperature—most frozen pizzas and ice cream wouldn’t exist without serious thermal engineering.

- Separation Operations: This includes things like filtration, centrifugation, and sieving. Dairy factories use filtration to separate cream from milk. Juice processing needs sieving to keep out pulp or seeds. Every coffee filter in your kitchen is a miniature version of this unit operation.

- Chemical and Biological Operations: Fermentation and enzyme treatments count here. When you see products like yogurt, cheese, or bread, you’re looking at food that’s been shaped by bacteria or enzymes. These steps add shelf life, flavor, or even make food easier to digest.

Here’s a snapshot table of where these operations pop up most:

| Unit Operation | Common Foods | Main Goal |

|---|---|---|

| Mixing | Bread, cake, salad dressing | Uniform texture and flavor |

| Blanching | Frozen vegetables | Stop enzyme action, lock color |

| Filtration | Milk, beer, juice | Remove solids/impurities |

| Pasteurization | Milk, juice, eggs | Kill harmful bacteria |

| Cooling/Freezing | Ice cream, ready meals | Preserve freshness |

One cool fact—over 90% of packaged foods on grocery shelves have gone through at least three types of unit operations before you see them. No wonder food technologists call them the backbone of the business.

Real-World Examples and Tips

Let’s get into the nitty-gritty. Every food processing plant uses unit operations, but the way they do it changes from product to product. For example, making french fries at scale doesn’t just mean cutting potatoes and tossing them in oil. Here’s a basic breakdown:

- Cleaning and Sorting: Fresh spuds come in covered in dirt and rocks. High-powered water jets and vibrating screens kick off the process.

- Peeling and Cutting: Machines peel and slice potatoes into perfect fry shapes at eye-watering speeds. Waste skins often become animal feed.

- Blanching: Fries take a hot water bath for about two minutes. This step kills bacteria and stops enzymes that wreck flavor and color.

- Frying: A massive continuous fryer turns the slices golden—and a quick freeze locks it all in.

- Packing: An automated line seals fries in cold, moisture-proof bags so they stay crisp until you crank the oven up at home.

Each of these unit operations needs tight control. Mess up blanching and you’ll get soggy fries with weird colors. Goof on cutting and some fries will cook too fast or too slow. Sensors and timers everywhere help keep things consistent.

Here’s a quick look at how water and energy use stack up for common unit operations in a mid-sized plant:

| Unit Operation | Average Water Use (L/hr) | Typical Energy Use (kWh/hr) |

|---|---|---|

| Washing | 3000 | 5 |

| Blanching | 500 | 15 |

| Frying | 200 | 80 |

| Packing | 20 | 2 |

Tip: Want your fries to have that restaurant-style crunch at home? Big factories double fry—once to cook, once to crisp. You can totally copy this at home by frying, freezing, and then frying again before eating. It’s a small trick with a huge payoff in texture.

Let’s switch gears. Think about milk processing. Chilling the milk right after milking is a unit operation that’s non-negotiable. If milk isn’t cooled within two hours, spoilage bacteria go wild and quality nosedives. That’s why in places like Ireland, more than 95% of dairy farms use on-site cooling tanks, often chilling milk to 4°C or lower before it ever hits a truck.

One more insider tip: in fruit juice production, filtration (removing pulp and bits) is a unit operation that’s not just about looks. Clearing out the fruit solids keeps juice fresher longer and stops the bottle from fermenting and turning into a science project in your fridge.

Why Unit Operations Matter

Every snack or meal you pick up from the supermarket owes its safety and flavor to good unit operations. Mess up a single step, and things can get gross or even dangerous fast. These steps aren’t just tradition—they’re backed by rules, science, and tons of trial and error. Big food recalls from the past, like the spinach E. coli scare in 2006, often trace back to sloppy cleaning or cross-contamination during processing. This is why manufacturers don’t just wing it; they have strict schedules, checklists, and automatic sensors everywhere.

Unit operations are the backbone for keeping food safe, keeping taste consistent, and cutting down waste. Hospitals track foodborne illnesses with scary numbers. According to the CDC, about 1 in 6 Americans get sick from contaminated foods yearly. That means your frozen pizza or yogurt needs every cleaning, heating, and chilling step done right—every time.

Quality matters, too. Want chips with the perfect crunch? That comes from precise frying and cooling steps. Hate soggy spinach in your salad bowl? That’s all about quick blanching and chilling. Even packaging steps count. Damage at that last stage can let in air, causing big losses—the USDA reported in 2023 that 30-40% of food produced in the U.S. goes to waste, much of it linked to spoilage that starts after bad handling or packaging.

Here’s how unit operations shape what lands on your dinner table:

- Food Safety: Stops harmful bacteria, pests, and toxins from sneaking through.

- Uniformity: Lets a brand sell the same taste and texture in every pack.

- Shelf Life: Good steps keep food fresh and safe much longer.

- Efficiency: Smart processes reduce waste and keep costs down.

| Operation | Main Goal | Risk if Skipped |

|---|---|---|

| Washing | Remove dirt/pesticides | Contamination |

| Heating | Kill pathogens | Food poisoning |

| Freezing | Preserve quality | Spoilage |

| Packaging | Prevent recontamination | Short shelf life |

So next time you snack, remember—every smooth bite or fresh crunch is thanks to these behind-the-scenes steps. People in the food business swear by good operations because they just work. And for anyone into food science, understanding these moves is basically ground zero for doing the job right.

Write a comment